Metal Stamping Dies Trends Shaping Modern Industrial Fabrication

Industrial fabrication increasingly relies on efficiency and precision. Metal stamping dies evolve to meet these demands. Modern trends focus on automation, precision, and material optimization. Manufacturers achieve complex shapes faster with reduced errors. Continuous innovations lower production costs while improving output quality. Understanding these trends underscores the crucial role of metal stamping dies in modern factories. They shape both manufacturing efficiency and product reliability. Metal stamping dies remain a cornerstone of industrial fabrication.

Automation Driving Production Speed

Automation in metal stamping dies streamlines production lines, enhancing efficiency and productivity. Robotic feeders and automated presses reduce manual handling. Manufacturers can perform multiple operations in a single pass. Faster cycles improve output and shorten lead times. Automation also enhances safety by minimizing the need for human intervention. Production lines achieve higher consistency and less downtime. Automation is a defining trend in modern metal stamping dies. Metal stamping dies boost industrial efficiency through automation.

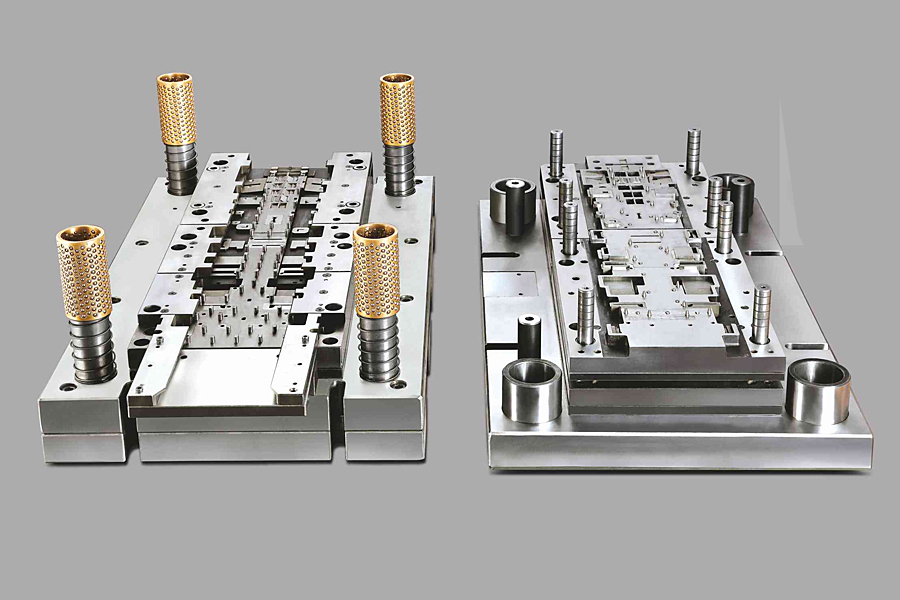

Enhanced Precision and Accuracy

Precision is critical in modern industrial fabrication. Advanced metal stamping dies maintain tight tolerances across thousands of parts. Uniformity ensures seamless assembly and high-quality final products. Precision reduces defects and minimizes rework or scrap. Consistency is key for industries like electronics and automotive. Engineers rely on accurate stamping dies to meet stringent specifications. Improved accuracy is a significant trend in metal stamping dies. Metal stamping dies ensure the precise fabrication of components.

Material Utilization and Sustainability

Efficient material use becomes a growing trend in stamping dies. Multiple operations on one sheet reduce waste. Layout optimization maximizes raw material usage, cutting costs. Sustainable production aligns with environmental regulations and corporate responsibility. Less scrap translates into lower disposal costs and higher profitability. Manufacturers now prioritize dies that minimize material losses. Material optimization drives modern metal stamping dies trends. Metal stamping dies sustainably enhance resource efficiency.

Integration with Advanced Manufacturing Systems

Modern metal stamping die is integrated with fully automated production lines. Sensors and robotic systems manage material flow and positioning. Integration reduces production interruptions and improves quality control. Automated lines achieve higher throughput and operational consistency. Seamless integration is crucial for smart factories and Industry 4.0 initiatives. Integration supports real-time monitoring and predictive maintenance. Connectivity and integration define the future of metal stamping dies. Metal stamping dies effectively support advanced industrial systems.

Rapid Prototyping and Product Development

Contemporary metal stamping dies accelerate prototyping cycles. Designers can quickly test and refine components before mass production. Rapid iterations reduce development timelines and improve product quality. Manufacturers respond faster to market trends and innovation demands. Prototyping with advanced dies enables cost-effective experimentation. Development speed is a growing priority in industrial fabrication. Rapid prototyping is a key trend in the development of metal stamping dies. Metal stamping dies support efficient product development processes.

Durability and Long-Term Reliability

High-quality metal stamping dies offer long service life. Precision machining and durable materials reduce wear and tear. Predictable maintenance schedules minimize unplanned downtime. Reliable dies maintain production efficiency over time. Longevity improves return on investment and operational consistency. Industrial facilities depend on durable dies for uninterrupted fabrication. Durability and reliability are central trends in modern metal stamping dies. Metal stamping dies provide dependable long-term performance.

Customization for Specialized Applications

Customized metal stamping dies meet unique industry requirements. Tailored designs address component complexity and material variations. Custom dies allow manufacturers to optimize efficiency for specific products. Flexibility in design enhances competitiveness and reduces lead times. Industries like aerospace and electronics benefit from bespoke solutions. Customization ensures that dies meet precise operational needs. Tailored solutions are shaping the latest metal stamping dies trends. Metal stamping dies are designed to meet specialized industrial requirements.

Conclusion on Metal Stamping Dies Trends

metal stamping dies trends focus on automation, precision, material efficiency, integration, prototyping speed, durability, and customization. These innovations improve industrial fabrication productivity, quality, and sustainability. Manufacturers that adopt modern metal stamping dies gain competitive advantages in terms of speed, accuracy, and cost-effectiveness. Ongoing innovations ensure stamping dies remain central to advanced industrial processes. Metal stamping dies continue to shape the future of manufacturing efficiency.

Basanti Brahmbhatt

Basanti Brahmbhatt is the founder of Shayaristan.net, a platform dedicated to fresh and heartfelt Hindi Shayari. With a passion for poetry and creativity, I curates soulful verses paired with beautiful images to inspire readers. Connect with me for the latest Shayari and poetic expressions.