Understanding Carbon Resistive Ink: Composition and Functionality

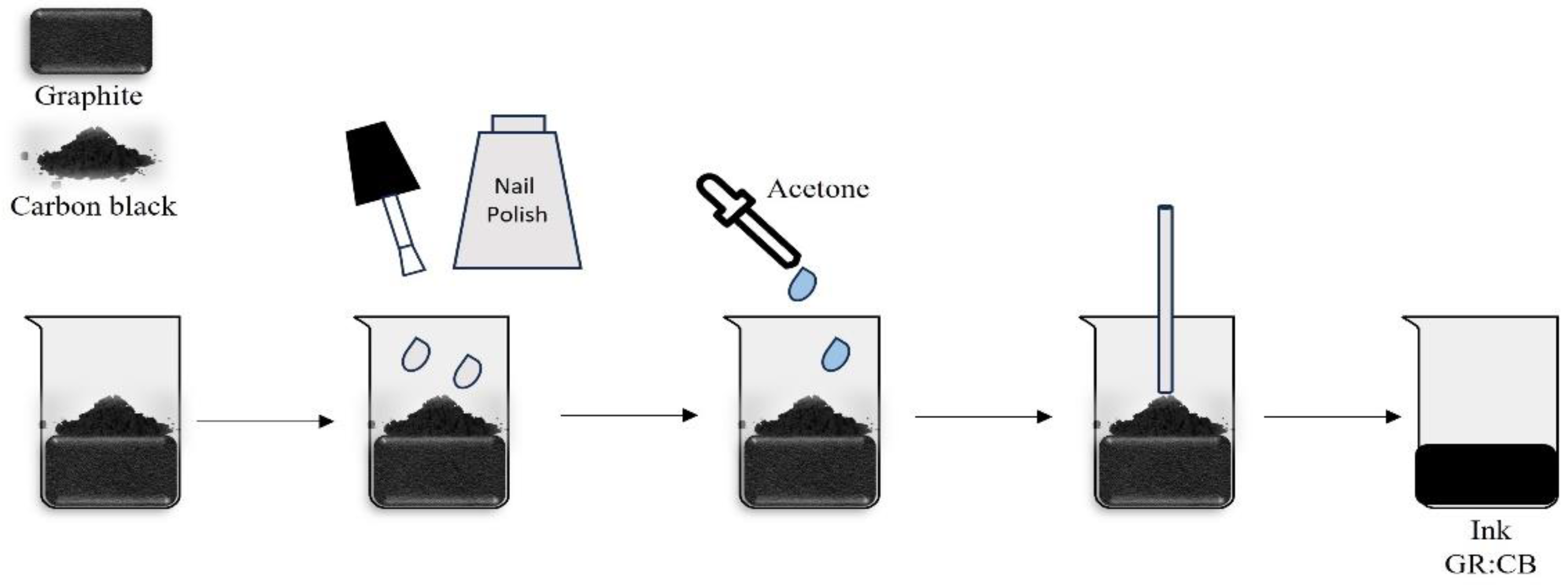

Carbon resistive ink is a specialised mix due to its discrete electrical conductivity, resistance characteristics, which find a common application in the printing and electronic industries. The kind of ink used may typically be a mixture of graphite or carbon black in finely powdered form, dispersed in a solvent and an adhesive binder of the polymer type. The ink can be formulated to either conduct electricity or produce some resistance value when dried on a surface. The nature and the number of particles of carbon used determine the properties of carbon resistive ink significantly. Generally, the greatest levels of concentration equate to the least resistance and high-conductivity ink. The binder system is also an important factor since it ensures flexibility, long-term stability, and compliance with the substrate.

- Applications of Carbon Resistive Ink in Modern Electronics: The carbon resistive ink is being used in a vast number of electronic components, and particularly in electric components where power consumption should be low, flexibility, and cost are important. One of its most common uses is making membrane switches, essentially a conductive strip on a flexible piece of plastic. The membrane switch serves as a type of standalone checklist that can be used to send information or perform an action when pushed. Devices such as industrial keypads, medical equipment, microwave ovens, and remote controllers all have these switches. Carbon resistive ink allows pressure sensitivity in touch-sensitive screens and sensors by altering resistance in response to pressure. It is also utilised in wearable technology, smart packaging, and automotive systems because of its versatility. In each of these situations, carbon resistive ink is a material of choice for low-voltage and signal-level applications due to its robustness, environmental stability, and adjustable electrical performance.

- The Carbon Ink Printing Process: Carbon-based ink is transferred to controlled areas by using a specialised means known as the carbon ink printing process, to generate resistive or conductive traces. The process can be conducted after various techniques, depending on the required precision, cost, and scale of production. Some of them are screen printing, inkjet printing, or gravure printing. Screen printing has remained the most common way of applying carbon-resistive ink due to its ease of application, high productivity, and application to various surfaces, such as non-destructive detachment. In the process, a mesh stencil is required to transfer the ink to the substrate, and finishing is prevalent with the use of curing, usually heat or UV. Inkjet printing is becoming increasingly popular, and is particularly attractive in low-volume and prototype work, as it is relatively cheap and wasting the ink is minimal, even at high resolutions, making direct contact unnecessary. The printed circuit properties, including the final electrical properties, the adhesion, and the durability, greatly depend on the choice of the substrate.

- Advantages and Limitations of Carbon Ink Printing: Carbon ink printing is very common today in several industries due to its several benefits. One of the main advantages of using it is that it is cheap and especially when compared to metallic inks, which are usually copper or silver-based. The large-scale production of carbon black is ideal due to the low costs of materials, besides simple processing procedures. The chemical stability, the corrosion resistance, and the environment resistance of the carbon ink also make them suitable when outdoor and industrial use is the intended target. It can also be adjusted to reach specific resistance levels, and is very flexible, being able to print on hard and soft surfaces. Printing by carbon ink can be associated with various disadvantages, however. The conductivity of carbon inks is less than metallic ones, and it might not be adequate to reality in high-power or high-energy applications. Microcracks or even higher resistance can also be caused by recurring mechanical bends over time in certain formulations.

- The Role of Carbon Black Powder in Ink Formulation: The carbon black powder, the main component in the carbon-based inks, offers electronic applications with the necessary conductive or resistive capabilities. This dust is highly finely powered soot-like solid made by means of imperfect combustion of hydrocarbons and containing a highly complicated nano architecture and high surface area. The electrical output of the ink, its viscosity and printability, as well as mechanical strength, are heavily determined by the type, size, and treatment of the carbon black particles’ surfaces. Smaller particle sizes usually give better conductivity, but application dependability could be affected since they exhibit more viscosity. To obtain the required resistance, which can vary from a few ohms to many megaohms per square, the carbon black content in resistive inks is changed.

- Environmental and Safety Considerations in Carbon Ink Manufacturing: As dry carbon black powder, which is breathable, can be rather toxic in case of its inhalation in large amounts, working with this substance presupposes using dust management and personal protective devices. The risks that are present are a lot lower in the ink formulations when the carbon black is contained in a solvent or polymer substrate. However, which are solvent-based carbon ink is known to release volatile organic compounds, which are harmful to the environment and even human health. To counter this, the usage of water-based formulations or formulations that do not contain solvents is also being increasingly used. Trash management and recycling should also be seen as another significant aspect of ethical manufacturing. Most businesses are also converting to more environmentally friendly solutions that still operate properly. Working with bio-based binders and biodegradable carriers for carbon inks has been prompted by the need for sustainable materials, providing a bright future to produce eco-friendly devices.

Modern electronics require carbon resistive ink, carbon ink printing, and carbon black powder as a unique combination of low cost, high flexibility, and practical performance. These materials have made possible the full spectrum of applications that require high degrees of flexibility, ruggedness, and reliability in conductivity, such as printed sensors, membrane switches, wearable technologies, and car controls. Carbon black powder has the advantage of strengthening the long-term stability of the printed circuits and the ability to reduce the amount of resistance to a high degree. Carbon-based inks are getting increasingly significant as industries want to pursue technologies that are not only less heavy, energy-saving and environment-friendly. The Future of Carbon Ink Printing: The future of carbon ink printing is bright due to the ever-growing materials and printing uses, especially in the rapidly growing fields of smart electronics, Internet of Things devices, and environmentally friendly production.

Basanti Brahmbhatt

Basanti Brahmbhatt is the founder of Shayaristan.net, a platform dedicated to fresh and heartfelt Hindi Shayari. With a passion for poetry and creativity, I curates soulful verses paired with beautiful images to inspire readers. Connect with me for the latest Shayari and poetic expressions.